| Author |

Message |

michael laughlin

New member

Username: Techfx

Post Number: 2

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 14, 2007 - 01:54 pm: |

|

I have recently purchased what seems to be someone's half finished project. no matter what belt i've tried (max 1078 or 1092 and ski doo 1103 and the very narrow belt that came on the machine) the machine has barely any climbing power. even 15 deg. can be difficult sometimes and the engine bogs down any time I try to start off. I find myself pulling the sticks back, revving the engine then pushing forward quite a bit. it also doesn't seem like it wants to reach full speed unless going down hill (the engine seems to running fine/ revs up). It has an OEM ski doo clutch.

Is this a clutch/belt issue, engine or possibly the transmission?

This is my first machine. (haven't worked on one since I was 14 w/ my father 14 years ago).

thanks,

Mike

techfx_mnl@yahoo.com |

Josh

Junior Member

Username: Mccastlej

Post Number: 12

Registered: 12-2006

Posted From: 24.11.110.240

Rating:

Votes: 1 (Vote!) | | Posted on Sunday, January 14, 2007 - 02:14 pm: |

|

Did it originally have a 4 stroke engine in it? If so, the torque convertor is setup different and you will need to change it, or the setup. Your 503 should have way more than enough power to make your machine almost fly. I'd guess from not seeing it in front of me that it's all in your torque convertor. Someone could have messed with the clutch too. Can you watch, or have someone else watch the centrifugal clutch and torque convetor while you are driving? |

Josh

Junior Member

Username: Mccastlej

Post Number: 13

Registered: 12-2006

Posted From: 24.11.110.240

Rating:

Votes: 1 (Vote!) | | Posted on Sunday, January 14, 2007 - 02:15 pm: |

|

Did it originally have a 4 stroke engine in it? If so, the torque convertor is setup different and you will need to change it, or the setup. Your 503 should have way more than enough power to make your machine almost fly. I'd guess from not seeing it in front of me that it's all in your torque convertor. Someone could have messed with the clutch too. Can you watch, or have someone else watch the centrifugal clutch and torque convertor while you are driving? |

Fred Sowerwine, Montana's Max dealer

Advanced Member

Username: Fred4dot

Post Number: 221

Registered: 01-2005

Posted From: 216.166.168.53

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 14, 2007 - 02:21 pm: |

|

Mike, My guess is that it is a drive pulley and driven pulley spring issue (and I do not have the expertise to help you). If you have a good snowmobile shop around, that is where to go for advice. You have to match the engine RPMs to the drive pulley and the torque requirements to the driven pulley. It probably is also a belt issue. When everything is working as it should, the drive belt will ride to the outer edge of the drive pulley when you are at full RPMs and the belt will ride toward the outer edge of the driven pulley at slow speeds. When required by load conditions, the driven pulley will adjust to maintain engine RPMs.

The T-20 tranny either works or not. If you are sure your engine is revving as it should and doesn't need a governor adjustment, that leaves the automatic clutch/torque converter assemblies. Engine switches most always cause these types of problems. |

michael laughlin

New member

Username: Techfx

Post Number: 3

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 14, 2007 - 02:39 pm: |

|

Thanks for the info,

I believe it originally had a 2 stroke (due to the sticker about mixing oil in the fuel on the side of the body and it's a 70's machine according to RI). Unfortuanely I live in southern california so, not too many snowmobile shops around here. I may have to suck it up and drive 2-3 hours to the mountains to find one. |

Josh

Junior Member

Username: Mccastlej

Post Number: 14

Registered: 12-2006

Posted From: 24.11.110.240

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 14, 2007 - 03:25 pm: |

|

It's fairly simple to figure out yourself. As I asked, can you see the clutch and torque convertor while you are driving it? |

michael laughlin

New member

Username: Techfx

Post Number: 4

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 14, 2007 - 04:53 pm: |

|

it would be difficult to see while driving - it's stock so none of the body is cut away... I have seen the engine clutch close while reving it up in neutral. |

Josh

Junior Member

Username: Mccastlej

Post Number: 16

Registered: 12-2006

Posted From: 24.11.110.240

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 14, 2007 - 05:12 pm: |

|

Can you get a picture of your torque convertor? One thing you can do is to adjust your torque convertor. I'm not sure which setup they used, but the torque convertor on my Argo had different holes that the end of the spring could be set in for a different preload. You will want to make it so the torque convertor is the hardest to open. That 503 has more grunt than the stock engine, and the spring on the torque convertor could be getting worn. The other thing you could do would be to put a stronger spring in the clutch, or get lighter weights for your clutch. |

Fred Sowerwine, Montana's Max dealer

Advanced Member

Username: Fred4dot

Post Number: 222

Registered: 01-2005

Posted From: 216.166.168.53

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 14, 2007 - 07:12 pm: |

|

Mike, You can solidly block (with wood blocks at the corners under the chain troughs - I use a 10 to 12 inch 6x6 and an 8 inch 4x4) your machine up (with all wheels off the ground) and put it in gear. You won't have much load (you can also check your axles for trueness), but you can watch the pulleys. With the engine off, the drive belt should be tight enough that it is hard to get off by walking it off the driven pulley without loosening any bolts but not so tight that it won't come off. A new belt should be 1 and 3/16 inches wide (replace if less than 1 & 1/16" wide). With the engine off, there should be 1 and 1/4 inches of deflection, but deflection is very hard to measure. A belt too long (too loose) will not allow full top speed. A belt too short (too tight) will not allow the pulleys to open and close correctly and will never disengage. If your belt is right and the pulleys look like they are opening and closing correctly, it is a spring (and weight issue). You can probably call the factory or Richard Clark and they can get you what you need. If you don't want to fool with it, you can have a lawn mower repair shop or ag implement place work on it for you. I have never been into either pulley, but there most likely is someone on here that has that will talk you through the process. |

Mike Cummings

Member

Username: Hydromike

Post Number: 43

Registered: 03-2005

Posted From: 141.149.254.227

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 15, 2007 - 10:05 am: |

|

Mike,

I run a 503 Rotax in my '72 Attex. When I first had it set up, I ran the stock (two stroke) torque converter on the T-20, and the stock Attex (originally 400 JLO) Salsbury clutch. I also ran the stock 1 3/16" wide belt, Gates #6096. If your early Max (BigMAX model?) originally was powered by a two-stroke, I think that the torque converter should work O.K. The Rotax takes the standard 30mm taper that most clutches offer, so if you're up to it, I'd consider upgrading to a comet 102C, which is very easily tuned to match the output of your engine, and really make your Max hum along. I can give you further info. on what's "working"  for my machine. for my machine.

And if I could just interject one other thought, I am EXTREMELY happy with the fact that no one suggested yanking this precious jewel out of your Max and replacing it with a lawn mower engine. THANK YOU, THANK YOU, THANK YOU!

~mike |

Mike Cummings

Member

Username: Hydromike

Post Number: 44

Registered: 03-2005

Posted From: 141.149.254.227

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 15, 2007 - 10:11 am: |

|

Mike,

I run a 503 Rotax in my '72 Attex. When I first had it set up, I ran the stock (two stroke) torque converter on the T-20, and the stock Attex (originally 400 JLO) Salsbury clutch. I also ran the stock 1 3/16" wide belt, Gates #6096. If your early Max (BigMAX model?) originally was powered by a two-stroke, I think that the torque converter should work O.K. The Rotax takes the standard 30mm taper that most clutches offer, so if you're up to it, I'd consider upgrading to a comet 102C, which is very easily tuned to match the output of your engine, and really make your Max hum along. I can give you further info. on what's "working"  for my machine. for my machine.

And if I could just interject one other thought, I am EXTREMELY happy with the fact that no one suggested yanking this precious jewel out of your Max and replacing it with a lawn mower engine. THANK YOU, THANK YOU, THANK YOU!

~mike |

liflod

Advanced Member

Username: Liflod

Post Number: 126

Registered: 01-2005

Posted From: 151.201.211.103

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 15, 2007 - 10:28 am: |

|

It sounds like your belt is too loose. It may be wide enough, but I think you need to move the engine back to tighten the belt. I had the same problem with my first Attex. |

michael laughlin

New member

Username: Techfx

Post Number: 5

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 15, 2007 - 11:44 am: |

|

Thanks for all of the info to take into consideration. I will try to put the machine up and watch the clutch/torque converter and get a photo of the setup this weekend. It does seem like whatever belt I try is too wide for the ski doo clutch (whether the engine is moved forward or back). I've heard that the belt shouldn't spin when the engine is at Idle but, It does w/ every belt I've tried, loose or tight. Upgrading the clutch sounds like a logical step. getting the belt off is a pain requiring some prying between the bolt on the bell housing and the plastic body so, I can't have a clutch that sticks out too far.

I think if I ran something other than a fast 2 stroke, my father and uncle would disown me (both ex 70s racers). Unfortunately, living in California, If I stay out here too long, I may have to find a more eco-friendly replacement - without sacrificing speed/power of course. |

michael laughlin

New member

Username: Techfx

Post Number: 6

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 15, 2007 - 11:48 am: |

|

Thanks for all of the info to take into consideration. I will try to put the machine up and watch the clutch/torque converter and get a photo of the setup this weekend. It does seem like whatever belt I try is too wide for the ski doo clutch (whether the engine is moved forward or back). I've heard that the belt shouldn't spin when the engine is at Idle but, It does w/ every belt I've tried, loose or tight. Upgrading the clutch sounds like a logical step. getting the belt off is a pain requiring some prying between the bolt on the bell housing and the plastic body so, I can't have a clutch that sticks out too far.

I think if I ran something other than a fast 2 stroke, my father and uncle would disown me (both ex 70s racers). Unfortunately, living in California, If I stay out here too long, I may have to find a more eco-friendly replacement - without sacrificing speed/power of course. |

Mike Cummings

Member

Username: Hydromike

Post Number: 45

Registered: 03-2005

Posted From: 141.149.254.227

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 15, 2007 - 04:11 pm: |

|

I keep all of my belts adjusted a bit on the tight side. My torque converter is always spinning, even at idle. I don't have spring loaded laterals on my machine, so if you let go of the sticks, it's always in "neutral" so to speak. I honestly don't see it doing any harm if the driven clutch is spinning at idle. It's a bit harder to get in gear, but that's par for the T-20 course. Get it tight enough so that you're getting top speed. THAT is the most important part. :o) |

michael laughlin

New member

Username: Techfx

Post Number: 7

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 15, 2007 - 11:34 pm: |

|

after looking at gates belt part exchange, the belt that I am currently trying is a 1078 which = gates 6096. I'm not sure if the max t-20 clutch would differ from the attex t-20 clutch but, I'll try sliding the engine back and see if getting that size belt a little tighter helps. |

michael laughlin

New member

Username: Techfx

Post Number: 8

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 21, 2007 - 01:30 am: |

|

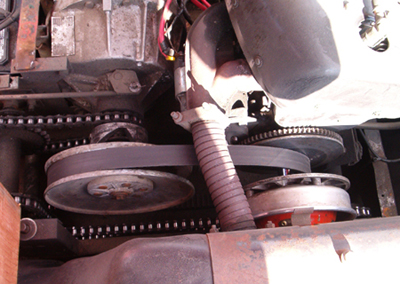

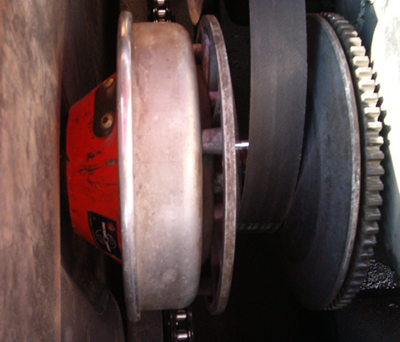

Well, I had time to go to my machine and get some photos but, didn't get to do much else

(it's 35 miles away from my house).

<img>

<img> |

michael laughlin

New member

Username: Techfx

Post Number: 9

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 21, 2007 - 01:47 am: |

|

try here.

|

Josh

Junior Member

Username: Mccastlej

Post Number: 19

Registered: 12-2006

Posted From: 24.11.126.88

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 21, 2007 - 12:06 pm: |

|

Looks to me like your belt is too long. |

philip w.cox

Advanced Member

Username: Philipatmaxfour

Post Number: 255

Registered: 01-2005

Posted From: 199.246.2.9

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, January 21, 2007 - 03:51 pm: |

|

Wow, I thought I had it tough getting my belt between the tranny pulley and the tub! your's is way worse. W.Philip Cox. Your belt looks loose to me. |

Mike Cummings

Member

Username: Hydromike

Post Number: 46

Registered: 03-2005

Posted From: 141.149.254.227

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 22, 2007 - 10:25 am: |

|

Wow, that's very loose, Mike. Try sliding the engine back about and inch (or more). If you don't have that much in the adjustment, I'd try a different belt. Some of the Ski-Doo clutchs (I'm not sure which ones) take a 1 1/4" wide belt, as opposed to the 1 3/16". That 1/16" makes a big difference.

I'd really like to know where the exhaust manifold is from. Is that a Rotax part, or is that home-made? I made my own exhaust manifold for the racer, but it's not perfect, and leaks a little oil past the gaskets. Are you running twin Mikuni 34mm carbs on this engine? Depending on what your sprocket size is on the jackshaft and the axles, I'd be looking for close to 40/45mph out of this machine, easily.

The 503 generates 52hp @6500 rpm, and a paltry 26 hp at about 4400 rpm. I guess the point is, you double the engines output in that ~2000 rpm window, and your Ski-doo clutch is geared to get a snowmobile moving on the snow when you're making that much power. In an ATV, you want to be able to use whatever power is available in the low RPM range. You don't want to be blasting around at 5-6 grand all day do you? Of course you do, but read on...

The Ski-doo clutch may be hampering you quite a bit. Your first message stated that you rev up the engine and push the sticks forward to get moving up a hill, and the engine bogs down quite a bit. This seems kinda contradictory to how that clutch should be performing. The 503 is still making PLENTY enough power at 3000 RPM (just off idle for a healthy two-stroke... ) )

to get the Max moving up a hill.

I see you have the electric start hooked up, and you probably enjoy that quite a bit. The 503 engine family (including the 277, 377 and 447) have to use the starting ring on the clutch for electric start, unless you go to a pricey ultralight setup which utilizes the MAG side starter. This will force you to retain the Ski-Doo clutch, but if you ever think about converting to manual start (or somehow retrofitting the Ski-doo starter gear to a Comet clutch) I have a few different combinations of Comet 102C spring and cam-arms that will make it perform like you may want. The 503 in my Attex is just about tuned like I want it to be, and it'll idle along happily at 15-20 mph at about 3000 RPM.

I still have 3500 RPM left to play with if the need arises. It's just nice to know it's there.

The first change would be to tighten that belt up, and hang on!

Good luck,

~mike |

michael laughlin

Junior Member

Username: Techfx

Post Number: 10

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 22, 2007 - 01:50 pm: |

|

Previous to trying the belt in the photo (which is about 1-3/16" wide = gates 6096 or dayco 1078) I did have a dayco 1092 that was 1-5/32" wide but, 4 inches shorter belt length. It did run better but, it still wanted to bog the engine a little to get going and didn't exactly seem to reach 40-45mph. If the ski doo clutch wanted a belt that 1/16 wider, wouldn't it engage at a hight rpm?

I'm not sure (nor probably is the seller who seemed to know nothing about this machine) about the exhaust manifold. I have a single mikuni carb (dual would be nice). I also have some oil leaking from the intake and exhaust manifolds - changing gaskets to see if that helps soon.

I think I need to hang on to the electric start for a while (I am about to rebuild the recoil for the second time). If the ski doo clutch is the only one that will fit this setup, is it at all tuneable? are there any others that might fit? (yes i have to use a cresent wrench to pry between the clutch and body to get the belt off).

-mike

|

Mike Cummings

Member

Username: Hydromike

Post Number: 48

Registered: 03-2005

Posted From: 141.149.254.227

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 22, 2007 - 04:06 pm: |

|

Any standard 10:1, 30mm taper clutch will fit, but if you want to retain the electric start, you need to stick to the Ski-doo clutch. I'm not sure if the Ski-doo clutch is tuneable. Its a pretty basic setup with, very similar to a Salsbury clutch originaly used on the machine (likely).

If the belt is too thin, the clutch needs to engage further in order to "grab" the belt, and really begin acting on the torque converter. If the belt is wider, the sheeves of the clutch don't need to move in as far (lower RPM) to "grab" the belt and begin to effectively drive the torque converter. At least this is the case with my experience going through several different belt widths on the Attex. I still can't figure out why it would be bogging down. You say it revs up fine without engaging the trans? Is compression pretty even on both cylinders (5% difference is OK)

Twin carb flanges are pretty common on ebay for this engine, and would really make is snort. You should be experienceing NO bog, unless you're pulling a Volkswagon behind you. I would check your muffler, too. The 503 family responds poorly to restricted exhausts, and equally well to a big fat expansion chamber sticking out of the back.

A stock Max exhaust designed for a 400 JLO won't help this beast breathe.

~mike |

Marc Stobinski

Member

Username: Jerseybigfoot

Post Number: 43

Registered: 06-2000

Posted From: 68.193.116.132

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 22, 2007 - 09:16 pm: |

|

Check the condition of the carb mount and make sure there is no cracks in the rubber and that the seals are good on the intake manifold. a vacuum leak at the carb intake will cause a bog also. You can also increase the torque converter diameter to obtain a lower gear ratio. The belt in the photo looks too loose and narrow for the converter. Also check your belt alignment for any top speed issues by observing it with the engine at its maximum safe speed in nutral. If the belt does not run straight you loose power and speed. |

michael laughlin

Junior Member

Username: Techfx

Post Number: 11

Registered: 11-2006

Posted From: 68.105.120.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, January 26, 2007 - 12:42 pm: |

|

I just removed the exhaust manifold to check an oil leak/replace gaskets. It's definately home made - they must have welded the original manifold to the rotax bracket. there's definately a slight restriction between the two. I could easily have $1000 in the correct exhaust setup.

To top it off, I just got laid off this week...

So, what's next?

Anyone want to buy a partially converted machine? |

Derek Hubbard

Member

Username: Justmax

Post Number: 50

Registered: 02-2005

Posted From: 75.179.52.62

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, January 26, 2007 - 02:12 pm: |

|

Hey Mike:

I'm sorry to hear about your bad news, but don't give up on the Max. Hold on to it untill you are in a better position to finish it. I have had my Max for three years now and till not done with it yet. My wife just had twins in December, so there goes my Max fix it budget for now. Keep your head held high, because you are the proud owner of Max!!! and when you get it right , you out ride and out run owners of lesser machines.

Derek |

Mike Cummings

Member

Username: Hydromike

Post Number: 49

Registered: 03-2005

Posted From: 141.149.254.227

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, January 29, 2007 - 09:35 am: |

|

Mike,

A homemade exhaust doesn't necessarily mean it won't perform as well or better than a "factory" Rotax exhaust. Several different machines from hover crafts, ultralights, and snowmobiles used the 503. The hard part will be fitting a workable exhaust within the tight confines of the Max. It almost looks like your exhaust manifold is an old JLO twin exhaust manifold that likely had the rotax flanges welded to it. That part of the manifold should flow reasonably well. If you can, try to take the muffler itself off and see if there's any material that's been jammed in there by your local rodents (seeds, leaves, grass, insulation, nuts, mud, cloth). I don't imagine there is much plugging it, or your engine would run very poorly.

My homemade manifold, though ugly, performs quite well with the ski-doo expansion chamber. If you're into finding something that works for your machine that isn't homemade, and that may require some modification of the exhaust routing, check out ebay for exhaust parts. The 503 Rotax came as optional equipment in the following machines:

Ski-Doo Stratos, Blizzard 5500, Skandic, Safari, Escapade, as well as their MotoSki equivalents (i.e., the MotoSki sonic, and others).

With all of these machines, there are several different exhaust configurations. Unfortunately, the mufflers/chambers are usually quite large, and as I said before, it will necessitate some serious rerouting. Your "cool" factor will go right through the roof, though.

Good luck with the machine, and your job...

~mike |