| Author |

Message |

Mike Maroni

Member

Username: Micmac

Post Number: 41

Registered: 07-2005

Posted From: 71.240.229.37

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, July 31, 2006 - 07:50 pm: |

|

I ordered some bearings from a bearing distributer near my house. I explained what the application was and he reccomended a dual set screw bearing rather than the accentric lock collar. Has anyone used these before? I'm wondering if the two set screws will cinch the axle tight enough. |

david berger

Senior Member

Username: Davidrrrd

Post Number: 410

Registered: 01-2005

Posted From: 72.72.14.129

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, July 31, 2006 - 08:06 pm: |

|

ALL DEPENDS, THEY WORK GREAT ON MY ATTEX,

MY ATTEX HAS DRIVE TUBE'S THAT NICELY FITS BETWEEN THE OUTER AND INNER BEARINGS AND THE DRIVE BOLT ALSO LOCATES THE AXEL QUITE WELL.

ON MY MaxII HOWEVER THE CHEEP ASS DRIVE TUBES ARE WAY TO SHORT TO HELP LOCATE THE AXEL.

IF I CAN FIGURE OUT WHAT TO USE FOR SPACERS MAYBE I CAN REPLACE MY CAM LOCKS TOO! |

Mike Maroni

Member

Username: Micmac

Post Number: 42

Registered: 07-2005

Posted From: 71.240.229.37

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, July 31, 2006 - 08:21 pm: |

|

David good to here from you. You've been quiet here lately. I'm using these on my max IV and I'd have the same problem that you have on the max II. I was wondering even with the eccess slop if the set screws would keep the axle located?

Also I was thinking about your problem of taking up slack and I came up with the idea of using spare lock collars as washers. I looked at mine today and it looks like one on either side of the sproket tube might work. I won't know until I get my machine back together.

I just completed the "Berger" tire mod. I put tubes in each tire as well. I hope it works. I've had this machine almost a year and have driven it a total of 12 hrs

But I havn't given up yet

Mike |

david berger

Senior Member

Username: Davidrrrd

Post Number: 411

Registered: 01-2005

Posted From: 72.72.14.129

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, July 31, 2006 - 08:49 pm: |

|

i dont think they would, however you could drill a shalow hole coresponding to each set screws local to help them locate your axel, but i beleave this is too much of a load for set screws!

I have looked at my growing colection of old lock collers too.

id take a rat tail file to the inside serfice for a little more clearence so they wont seaze to the axels. but i beleave i need diferent thicknesses to fill the gaps i have as they vairy from axel to axel for some reson, maybe when i try this new fraim that problem will disapear.

im still checking the posts every day, i have bin quiot due to the work im doin on the olean video. |

Larry Wright

Intermediate Member

Username: Xljimmy

Post Number: 76

Registered: 03-2005

Posted From: 69.221.235.172

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, July 31, 2006 - 09:53 pm: |

|

Just curious if you use the set screw type wouldnt that cause a leak in water between bearing and axle? Or is that not enought to matter a whole lot?

I just bought some locking collared bearing for my axle redo. Is there a problem with using the locking collars?

Larry |

Mike Maroni

Member

Username: Micmac

Post Number: 43

Registered: 07-2005

Posted From: 71.240.229.37

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, July 31, 2006 - 10:42 pm: |

|

Larry,

The axles fit fairly snug inside the bearing sleeve. The eccentric collars essentialy do the same thing as the set screws which is pinch one portion of the axle to hold it. so to answer your question I dont think it would make a difference in water tightness.

I started looking for a better bearing after my "new" TSC bearings detonated after only a few hrs. I have the older smaller diameter bearings and their weakness is the thinness of the locking cam area. This tends to break easly.

I whent to a local bearing distributer and told him what I would be using it for. He said that eccentric lock collars are really designed for single direction applications. IE if you reverse direction you may loosen the collars. He recomended a bearing with the two set screws. for the reason above and to get rid of the thin eccentric cam.

I'm going to call him again before I install them to find out the strength in locating the axle |

david berger

Senior Member

Username: Davidrrrd

Post Number: 412

Registered: 01-2005

Posted From: 72.72.14.129

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, August 01, 2006 - 09:07 am: |

|

keeping them set screws tight without locktight?

hmmm timothy schotanus has replaced some with hex head bolts, looks like a good idea.

id try it. |

Mike Maroni

Member

Username: Micmac

Post Number: 44

Registered: 07-2005

Posted From: 71.240.229.37

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, August 01, 2006 - 09:57 am: |

|

David,

I replaced the set screws on my inner bearings with hex head screws. When I pulled the axles to replace the outer bearings all but 2 of the inner cams were broken. This has to be from the hex head screws and most likely the torque I applied to them. In contrast the outers where I used only the set screw were intact. So I would use caution (not over torque) using the eccentric cams with hex heads. |

christopher j Davison

Junior Member

Username: Chris_davison

Post Number: 11

Registered: 06-2006

Posted From: 67.51.158.131

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, August 03, 2006 - 09:09 pm: |

|

hey has anyone tried the bearings that have a threaded collar as you tighten it the bore gets smaller and clinches the shaft? Also they make two bolt shaft collars tighten it down next to a bearing and the shaft cant move. Mcmasters cat.

page 1070 in cat #112 |

Marc Stobinski

Junior Member

Username: Jerseybigfoot

Post Number: 11

Registered: 06-2000

Posted From: 68.193.116.132

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, August 04, 2006 - 07:49 pm: |

|

The two bolt collars work very well but are expensive if you add the cost of the bearing and the collar against the cost of the excentric collar bearing. You also have to determine which way the thrust is on the axle relative to where you want the collar. some machines have sprockets with axle tubes or hubs that position aginst the bearing limiting the thust outward and dont need collars. Newer Argos have large bearing for both inboard and outboard and use the inbaard bearing to handle most of the thrust. It depends on your machine. Old Scramblers use spacers between the sprockets and bearings for outboard thrust and smaller inboard bearings for the inboard thrust which I could never understand but it works.

Excentrics work well if the axles re in good condition and the surface is smooth and round. The collars work well on rusty or pitted axles. |

Mike Maroni

Member

Username: Micmac

Post Number: 45

Registered: 07-2005

Posted From: 162.84.72.111

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, August 21, 2006 - 06:07 pm: |

|

Ok an update on the double set screw bearings. They have not worked very well. I have all of the outer bearings double set screw and three of the inner bearings as double set screw and three of the inner bearings as eccentric collars.

I have found that the inner eccentric cam / outer double setscrew set up works well. the three axles with the double setscrew on the inner and the outer tend to have the setscrews work their way loose.

I like the set screw bearing because it gets rid of the thin walled collar. Which is the reason I changes them

This is what I'm thinking of doing: Replace the remaining three inner bearings with the eccentric collared bearings and as an added measure I was considering using two piece locking collars on the outside flush to the outer bearing.

My question is what direction does most of the force to these axles go. I would think that it would be inward when skid steering. If I go with the above then any outward force would be offset only by the eccentric inner bearing and the setscrews on the outerbearing. Do you guy's think it will be enough?

I think this machine orginaly came with bushings for the inners. Did these bushings retain / locate the axle at all? I'm tring to judge if the above would be strong enough to locate the axle. |

david berger

Senior Member

Username: Davidrrrd

Post Number: 424

Registered: 01-2005

Posted From: 72.72.120.56

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, August 22, 2006 - 09:20 am: |

|

you know back when i mentioned hex head bolts in place of set screws i dident mean for the camlock bearings as much as for the dble set screw bearings, they needed every advantage they could get.

now your questions split several ways but it's still only one question,

the old bushings dident hold a dam thing, however its posable the axel could run agenced the fraim for inner thrust, i filled between the fraim and inner axel with a washer where there was room for the washer to suport the axel under a thrust load,

i used to have my solid axels bushing pocked drilled with a grease fitting to refresh from the inside out wich also lubed my axel/fraim thrust idea prity well, but after i added inner bearings(dble set screw without the stupid set screws in them)i could not use the greas fittings.

i even taper the ends of the axels a little to prevent them from seazing to bearings,

think about it, if an outer bearing freazes to an axel you can take the bearing and all off the machine and replace them without missing your lunch brake, a frozen inner took me 4 months to remove!

the factorys only means to hold your axels under inward thrus out outward thrust for nearly 30 years was done with the outer bearing alone, so traping this thrust load between the outer bearing and your fraim must be better!

if your mesurments while every things true alowes a certin size spacer to fit between an end of the drive tube and the outer bearing it will transmit the outward thrust load to the outer bearing just fine, and all the axels remain aligned just fine as well if space on the other ends taken up with a washer between end of axel and fraim where nesesary, your axel may move in or out 3/16" without messing your drive train up much.

the question is can you get your shims that cloase.

the single bolt threw the drive tube and axel is all you need to locate your axel corectly as long as the play is taken up as discribed.

i did it with an attex but there the drive tube was already perficly fit between the inner and outer bearings! no cam lock or set screws needed! |

david berger

Senior Member

Username: Davidrrrd

Post Number: 425

Registered: 01-2005

Posted From: 72.72.120.56

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, August 22, 2006 - 09:23 am: |

|

ooh yah mike i ment to ask, hows that tire mod working out for you?

(dont forget to check psi befor you ride caus at 2.5 the wether chainges everyday will reflect in tire psi chainges) |

Mike Maroni

Member

Username: Micmac

Post Number: 47

Registered: 07-2005

Posted From: 162.84.72.111

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, August 22, 2006 - 04:56 pm: |

|

Hi David

The tire mod is working out great I bought 2 new tires and put them in the center. On the 4 corners I have my older tires with decent tread on them. So far they have worked great. I bought tubes from J.C. Whitney for around $10 apiece. I understand what Fred was talking about when it comes to modifying things. However I'm going to be the end user on this vehicle and I don't mind trying stuff out. I think "THE BERGER" mod gives the best of both worlds the tires stay put and the tubes offer double protection against sharp rock etc..

Now about the bearing stuff, this is what I plan on doing:

I have taken out all the setscrews from the outer bearings and replaced them with 1/4 inch fine thread hex screws. The smallest I could find are 1/2" long. I might keep looking for some slightly shorter ones or cut the ones I have. They stick out a little far and I'm worried that they would be susceptible to damage. Even long grass would get caught on them.

The rear axles: the outer bearing I'm keeping the setscrew bearing. I'm going to put two piece locking collars on either side of this bearing. I have the clearance on between the frame and the axle tube for this. These clamp the shaft therefore they don't have to be right up against the sprocket tube. This should limit movement in either direction. Additionally I'm going to put an eccentric bearing on the inner side for added protection. I'm most concerned with these axles because of the limited clearance of the large drive sprocket. If that moves it could cause some serious damage.

On all the other axles I don't have enough clearance between the axle tube and the frame for a collar. I'm going to keep the set screw outers and the eccentric inners. also I'm going to put the two piece lock collars on the outer side of the outer bearing to help with inner thrust. There is only about 1/4 " between the sprocket tube and the frame. So if these move outward it won't be much and the smaller sprockets won't do any damage.

This whole process started because I would like to get rid of the eccentric collars and set screws. I'm not quite there yet.

One thing I have considered is cutting the outboard side of the other four sprocket tubes. This would allow for clearance at all the axles so I could put 2 piece locking collars on either side of the outer bearings on all the axles. This would sandwich the outer bearing between the two collars, locating the axle. My only concern is that all the forces inward and outward would be on the outer bearing alone. David do you think that would be too much for the bearing?

Sorry for the long winded response but that's about were I am so far.

Mike |

david berger

Senior Member

Username: Davidrrrd

Post Number: 428

Registered: 01-2005

Posted From: 72.72.120.56

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, August 22, 2006 - 06:48 pm: |

|

it is a little too much but thats exactly what the outer bearings have done for 30 years, the cam locks were holding them ok.

i havent thought of that idea you just mentioned, cutting the drive tubes to alow old cams as spacers.

thats a great idea.

you only need them between the tube and outer bearing, for the inward load you can fill the space at the end of axel to fraim with 3/4" washers.

this i have done for many years so far works great. |

Derek Hubbard

Member

Username: Justmax

Post Number: 34

Registered: 02-2005

Posted From: 71.64.127.199

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, August 22, 2006 - 07:36 pm: |

|

Have I been gone that long????? Oh My..... David used spell check....Please Do Not get Me Wrong .....David is a well of Knowlegde and I myself have used some of his suggestions after decoding his posts...So David PLEASE do not be offended.....and Thank You for adding some much this info board.. |

Mike Maroni

Member

Username: Micmac

Post Number: 49

Registered: 07-2005

Posted From: 162.84.72.111

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, August 22, 2006 - 08:18 pm: |

|

David,

Where do you put the washers? I think your putting them between the inner side of the sprocket tube and the inner frame? Or are you moving the inner bearing assemble outward toward the sprocket tube? Could you describe it in a little more detail?

As far as spelling I'm terrible myself what I do is type my message then copy and paste it into my email spell check then repaste it into my post. It's a little more work but man my spelling stinks! |

david berger

Senior Member

Username: Davidrrrd

Post Number: 429

Registered: 01-2005

Posted From: 72.72.120.56

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, August 22, 2006 - 10:37 pm: |

|

drive tubes stop several inches from anything that would be any help at all.LOL

no the axel wich is conected with that 1 bolt to the drive tube gos threw your new innner berings.

(the old bushings and 3/4" studs are still used right)the 3/4 studs are where i used my washers if my axels did not totch the fraim. |

Fred Sowerwine, Montana's Max dealer

Advanced Member

Username: Fred4dot

Post Number: 187

Registered: 01-2005

Posted From: 216.166.168.53

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, August 23, 2006 - 12:23 am: |

|

Mike, david has an older Max II that had an inner bushing and he converted it to an inner bearing.

david, the Max IVs all have inner bearings; just the older Max IIs (up until 1998, I believe) had the inner bushings. |

Howard Hoover

Member

Username: Howard_hoover

Post Number: 41

Registered: 10-2005

Posted From: 4.161.19.34

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, August 23, 2006 - 07:14 am: |

|

Dodge has a bearing called a Grip Tight that I am thinking about using. It is similar to a squeeze lock but different.

I have called a lot of places to check prices and

this place called Transmission & Fluid Equipment Inc. gave me the best prices here in INDY ask for Tom. if he still works there 317-916-2478.

I started to use Eccentric locking collars but saw these and took the others back. This is patented so I think that Dodge is the only manufacturer of this type of bearing. |

liflod

Intermediate Member

Username: Liflod

Post Number: 97

Registered: 01-2005

Posted From: 151.201.211.103

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, August 23, 2006 - 07:45 am: |

|

I have been having the same problem with my Max IV and the inner bearing eccentric breaking. I think it is caused by the axle trying to pull out of the machine and not the axle pushing in. RI has introduced snap rings on the axles to locate and hold the sprockets on the axle. I think adding a groove and snap ring on the axle stub on the inside of the inner bearing and antoher groove and snap ring to locate the axle against the eccentric collar would work. I'm wondering if I could groove the axle with a hacksaw while the axle is turning? If I had a lathe, I would have done it already. But if I had a lathe, I would machine the inner part of the axle to use a smaller diameter inner bearing and tap the end of the axle for a bolt that would definately keep the axle in place. I am also considering using 1 1/4 inch ID pipe to make the Berger axle spacer/locators. |

david berger

Senior Member

Username: Davidrrrd

Post Number: 430

Registered: 01-2005

Posted From: 72.72.24.123

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, August 23, 2006 - 08:45 am: |

|

OOPS SOMHOW I GOT CONFUSED INTO MAX II MODE,

ID HAVE TO LOOK AT A MAX IV TO SEE IF IT WORKS, BUT IF LANCE THINKS A PIPE WILL MAKE AN INNER SPACER THAN IT PROBLY WOULD, AS LONG AS THE DRIVE TUBE STAYS TRAPED BETWEEN THE BEARINGS IN THE CORECT POSITION THE AXEL WILL STAY PUT AS WELL AS IT IS HELD BY THE AXEL BOLT, (WORKS IN MY ATTEX) |

david berger

Senior Member

Username: Davidrrrd

Post Number: 431

Registered: 01-2005

Posted From: 72.72.24.123

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, August 23, 2006 - 09:33 am: |

|

HI Derek,

prehaps it has bin that long,

even worse than my useing spellcheck ~ sometimes i might be spelling correctly!

i did have a nice linex based pc with a super spellchecker built in,

while i connected threrw AOL it worked well.

so i jumped in with both feet when verizon DSL made me a great connection deal!

they confirmed that they suported my linex based pc so i took there deal, i kicked AOL free and Guess what: verizon's DSL DNS servers dont recognise and thusly dont suport my linex pc!

that sucks!

i have 1 year with verizon, i hope they fix this DNS server problem!

But back to my spelling~ sometimes it is ok, sometimes not~

probly (styleized word i use insted of probably) due to my long service with this verry forum. |

liflod

Intermediate Member

Username: Liflod

Post Number: 98

Registered: 01-2005

Posted From: 24.3.234.58

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, August 25, 2006 - 06:04 pm: |

|

I just took a look and measurements for my Berger axle spacers. I have enough old locking collars to use them as spacers. I will have to make my own washer/spacer to go between the sprockets. My 1999 Max IV has the splined axles and individual sprockets. My old 1978 Max IV has the sprocket tubes and bolts. |

david berger

Senior Member

Username: Davidrrrd

Post Number: 432

Registered: 01-2005

Posted From: 72.72.60.101

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, August 25, 2006 - 07:39 pm: |

|

lance, time scotanus has began chaingeing his splined sprocket sets with some he had made by local machinests.

he bought 6 splined hubs from some place and sprokets from another,

he did this to replace his singles with sprokets that shaired a single hub to more safely transmit the tork from one to another.

this way the axel dident have to take the punishment during the transfer from one to the other.

also he did it because he wanted to refresh his sproket sets with new ones anyway, this also gave him the opertunity to locate the set screw holes to places easyer to get at, and he used hex bolts as instead.

the hubs were prity big so maybe theyd make the perfict bases for a full lenth

(bearing to bearing)drive tube style drive and axel location system! |

Mike Maroni

Intermediate Member

Username: Micmac

Post Number: 51

Registered: 07-2005

Posted From: 162.84.72.111

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, August 25, 2006 - 11:01 pm: |

|

David,

I've been thinking on the bearing to bearing axle locator. I decided to go stay this route instead: 2 piece locking collars on either side of the outer bearing (I'm using a double setscrew without them installed). This will limit inward and outward motion. For the inner bearing I've decided to use the double set screw this hex head screws in place of the set screws. This set up will hold the in three places.

The reason I'm thinking against the bearing to bearing tube is for a few reasons:

1. I'm worried about cutting the tubes perfectly to fit. I would If they're not perfect there could be some wobbling leading to premature wear on the chains and sprockets.

2. The set up would only be good using the existing bearings. Any changes in frame, Bearing or flange position would make for problems locating the axle. I know not much should change but it limits flexibility with different bearing styles / manufacturers etc..

Don't get my wrong I think it's a great mod if someone can machine it to fit good. I only have a drill with a cutoff wheel. My chances of cutting it perfect are slim at best. I'm still going to look it over but I think the best I could do is the two collars and the hex nuts on the inner bearing. It gets rid of the setscrews as well as the thin walled eccentric collars that's the best I can hope for.

Liflod,

Are you still considering steel pipe? How do you plan on cutting it cleanly?

Mike |

Howard Hoover

Member

Username: Howard_hoover

Post Number: 42

Registered: 10-2005

Posted From: 4.161.108.47

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 01:08 am: |

|

www.dodge-pt.com/pdf/brochures/bearings/raps950_2.pdf

Check this link out for bearings or just try searching Dodge Grip Tight Bearings. This new lock puts locking pressure across the whole surface of the bearing. Not just in one or two spots on the shaft like a set screw. This is a Non Marring gripping collar. |

Howard Hoover

Member

Username: Howard_hoover

Post Number: 43

Registered: 10-2005

Posted From: 4.161.108.47

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 01:12 am: |

|

When and if you go to this link wait for it to load because it will show you some very good detailed pictures of the bearing & locking collar!!!!!!!!!!!! |

Howard Hoover

Member

Username: Howard_hoover

Post Number: 44

Registered: 10-2005

Posted From: 4.161.108.47

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 01:17 am: |

|

Set screws are going to become a thing of the past with this and other new technology.

This will be the bearing that I will use unless they come up with something better between now and the time I buy my bearings. These are top of the line & more expensive but you get what you pay for . |

david berger

Senior Member

Username: Davidrrrd

Post Number: 433

Registered: 01-2005

Posted From: 72.72.71.78

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 09:07 am: |

|

you know there is a spaner wrench you should use if you do decide on useing the locking coller bearings,

and id use em on the outside before the inside due to inposability to remove them if they sieze!

also there can be some side to side movement of axel due too space between the drive tubes and bearings, i think maybe 3/16 wouldent hurt the chaines and sprockets.

one reason i was looking for vairious size thicknesses for my spacers would be the chainges in future bearings ect.. ect.. as you said. |

Mike Maroni

Intermediate Member

Username: Micmac

Post Number: 52

Registered: 07-2005

Posted From: 162.84.72.111

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 11:25 am: |

|

David,

I've decided to not use lock collar bearings at all. Instead I'm going to use the 2 peice collars that clamp onto the shaft. I will use these on either side of the bearing. The collars have 2 decent size bolts that wouldnt strip like the small setscrews making removal easy even when rusty. When I do the mod I'll try and snap some pictures and post them.

Howard,

I think those bearings are great and I'm sure that's the direction most people will be going. For now I need a somewhat inexpensive set up that I can get bearings off the shelf. Do you happen to know how well these perform / seal in a contaminated environment? That's probably most important

Mike |

Howard Hoover

Member

Username: Howard_hoover

Post Number: 45

Registered: 10-2005

Posted From: 4.161.19.218

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 02:03 pm: |

|

I don't know how well they will perform with dirt & debris. But if you have a good axle seal on the outside like a triple lip radial lip seal from a company that makes shaft seals it should keep the most of the debris from ever reaching the bearing, unless you have a bunch of stuff on the inside of your machine. |

Howard Hoover

Member

Username: Howard_hoover

Post Number: 46

Registered: 10-2005

Posted From: 4.161.19.218

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 02:32 pm: |

|

Try these links from Busak & Shamban:

www.busakshamban.us/prod_global.htm?pid=271

www.busakshamban.us/prod_global.htm?pid=78

the first one is a triple lip radial lip seal

& the second is a PTFE shaft seal .

these are only two of the many seals the have available check it out. |

liflod

Intermediate Member

Username: Liflod

Post Number: 99

Registered: 01-2005

Posted From: 24.3.234.58

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 02:56 pm: |

|

Axle seals on a Max ?? That's wishfull thinking. |

david berger

Senior Member

Username: Davidrrrd

Post Number: 435

Registered: 01-2005

Posted From: 70.22.129.238

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 07:40 pm: |

|

while cheeper they preform just about the same. |

Howard Hoover

Member

Username: Howard_hoover

Post Number: 47

Registered: 10-2005

Posted From: 4.160.99.133

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, August 26, 2006 - 09:38 pm: |

|

You could make your own seal housings or have someone make them for you or even make a pattern for seal housings and have them cast out of aluminum. |

Mike Maroni

Intermediate Member

Username: Micmac

Post Number: 54

Registered: 07-2005

Posted From: 204.188.172.194

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, September 02, 2006 - 05:57 pm: |

|

Ok I finally finished my bearing project and it has worked out great!

I decided to do something slightly different after looking at the machine. As I mentioned in the first part, my goal was to get rid of the eccentric collars and setscrews. I have an older machine and have the smaller bearings so the thin wall on the eccentric part is a problem. The second thing was to keep the axles fairly easy to remove. This is what I did:

First I bought good quality double setscrew bearings with the idea of just using the setscrews. Well that didn't work that setscrews kept coming loose and I wanted a tough design and not one that was problematic. I liked the thick wall of these bearings so I decided to keep these, but locate the axle differently. I couldnít find an easy way to upgrade to the larger bearings so Iíve tried to make do with these.

I figured out that with the sprockets in their position I had exactly enough spacing between the sprocket tube and inner bearing to fit the two piece shaft collars I purchased (they are a 1/2 inch wide). I knew that the sprocket tubes were a bit too long on the outer side for this. I decided to cut all of the sprocket tubes on the outer side to fit the collars. The collars cinch the axle and hold it. With both collars inside the machine on either side of the sprocket tube the axle cannot move. It is held in place not only by the collars but also the collar's width combined with the width of the sprocket tube takes up all the space between the bearings. This way if a collar were to loosen up it would still be in place because it's sandwiched between the bearings and the sprocket tube. Also if the axle Bolt were to break, the collars will keep the axle in place. This will not happen if you just use spacers. No offense David Berger but I had on of these broken before and I wanted a backup just incase! Also I had some hex head screws that fit into the setscrew holes. I put them in the inner bearings just because. Although their not requred.

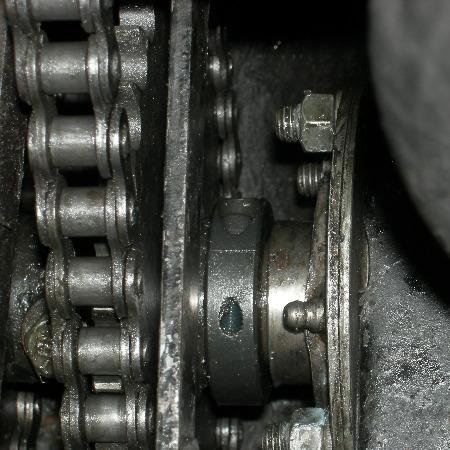

Here are some pictures of the Middle axle inner,outer, and the rear axle inner.

I want to thank everyone for their ideas. I hope that this helps anyone in a similar situation. Even though it was alot of work I wouldn't hesitate to do it again. |

Mike Maroni

Intermediate Member

Username: Micmac

Post Number: 57

Registered: 07-2005

Posted From: 204.188.172.194

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, September 03, 2006 - 05:37 pm: |

|

also I wanted to add how to figure out how much to cut off the axle tube. Before I pulled the axle I would remove anything gripping it and leave the sprocket bolt in. Then I would mark the axle on the outside of the outer bearing. I then tapped the axle outward until the sprocket tube touched the inside of the outer bearing. Then I would measure the difference between the mark on the axle and the bearing outer edge. I would now know how much spacing I had and would make up the difference so the 1/2 locking collar would fit. Probably better to cut just a bit (1/16 of an inch) more so you know everything will fit. |