| Author |

Message |

Larry Wright

New member

Username: Xljimmy

Post Number: 9

Registered: 03-2005

Posted From: 68.74.139.50

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, April 24, 2005 - 10:27 pm: |

|

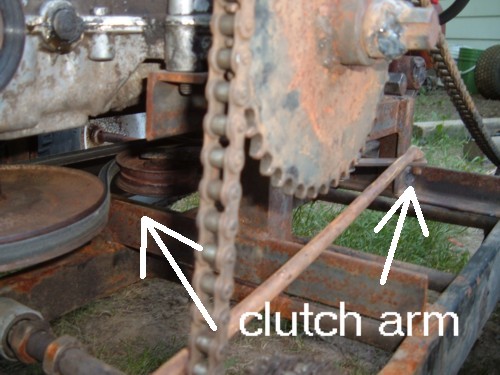

I am almost done with my amphicat project and cant wait to try it. So far total price spent including aatv and parts is around $150. The only thing left is clutch and tires. I was thinking of using a snowmobile type clutch but adding weight to it so it would activate at 4 stroke rpms. I need to save more dough to finish. I cut everything of the frame and started over. I put a vertical shaft vanguard in it running a 3 speed garden tractor tranny. The tranny is running upside down so pulley is low to keep the engine lower. From the tranny axle is a 42 tooth sprocket running to the 26 tooth on the axle to speed it up some from the garden tractor speed. I dont want it to go over 20mph but if it is still slow I can change the driven pulley on transmission. The brakes are a 4" band brake found on gocarts. I put them on the front axles for a easy linkage to levers and if chain breaks the are still connected to axle. It might not be top notch handler but should work. I dont see how it wouldnt work, but this is the only 6 wheeler I have ever had or seen and it was in pieces when i got it. What does everybody else think? Anybody see any possible problems. These picture are before the brakes were enginnered. It might be a couple of weeks yet but when it is running I will post results and more pictures. Thanks.   You can see cut out of hood for engine clearance. You can see cut out of hood for engine clearance.

|

Larry Wright

Junior Member

Username: Xljimmy

Post Number: 11

Registered: 03-2005

Posted From: 68.72.10.11

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, June 21, 2005 - 11:38 pm: |

|

I finally got to drive it today. Need to redo the brakes thought. They are 4" band brakes used on gocarts. I need to reverse the bands because the grab better in reverse and forward you cant hardly steer. When that is fixed I still wont be able to turn in reverse. That seems like the only problems though. I am thinking about going with hydraulic disc brakes with the calipers and lever assembly off a motorcycle but the disc will have to be fabricated because they cant be much bigger then 4" or they will hit the floor. Then I would get rid of the sticks and it would be controlled by the hand levers off a motorcycle. For the clutch I went with lawn mower style pulley on a lever, for know anyways. Havent decided on it being engaged with foot on the pedal or off it yet. The throttle and clutch was kinda mocked up for the first test drive just to see if it would work so I only did a lap around the house with a few dough nuts here and there. Plus it was in reverse so I could steer it. My FIRST 6 wheeler ride was backwards and still fun. I think the briggs vangaurd isnt charging. If anybody knows how to diagnose the problem, it would help lots. I checked all wires and it must be the square box thing with two wires(dont know what it is or does) or something else. I need to take picture yet of my current progress but when I do I will post them. Let me know what you think so far. Thanks Larry |

(Unregistered Guest)

Unregistered guest

Posted From: 141.149.254.227

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, June 22, 2005 - 02:24 pm: |

|

Larry,

I just came across your pictures, and wanted to compliment you on your work thus far. Looks like a lot of fun! A couple questions I came up with:

- with the transmission being mounted upside down, do you think lubrication is a concern? Since it was designed to operate right-side-up, will the oil reach all of the internal gears/bearings/bushings as needed?

- What are you using for a clutch? I can't see it too well, and I'm just curious what you've come up with.

Your work area looks exactly like mine when I'm in a frantic fabricating mood.

I have thought of the same hydraulic brake setup as you're speaking of. Mine is still in the thought stage though. Looking good, and keep us updated with the great pics!

`mike |

Larry Wright

Junior Member

Username: Xljimmy

Post Number: 12

Registered: 03-2005

Posted From: 68.72.10.11

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, June 22, 2005 - 10:13 pm: |

|

Mike,

I thought about the lube issue and I am not worried about it because it is a grease and not an oil.

I was going to use a variable speed clutch like on a snowmobile but they are expensive so I made a lever with a pulley on it to tighten the belt like most lawn tractors. I figure I can always change it back later if I come across an centrifical clutch because that would be ideal. I could have it engaged when holding the pedal down and disengage when foot is off or vise versa but haven decide on which yet. On the test drive I just had a rod that I held with my foot. I havent made a pedal yet.

I tried fixing the brake problem today but cannt figure out the best way to do it. It would be simple if pushing the sticks forward would apply the brakes but really dont want it that way. The band engages by moving forward. I think I might have to move the sticks upward to get the forward control movement on the bottom of the sticks when pulled back. Now I can only get the back movement when the stick are pulled back. (Sorry if that is confusing.)

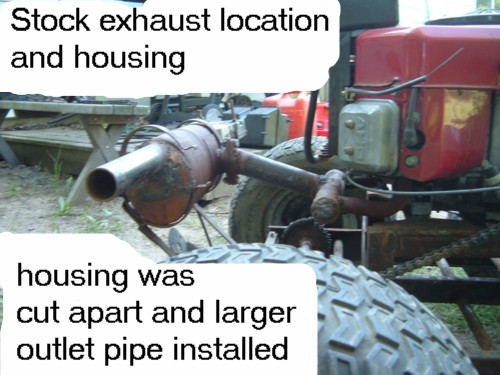

The muffler was cut in half and I cut out the little two stroke outlet and welded in a larger outlet pipe.

Larry

|

david berger

Intermediate Member

Username: Davidrrrd

Post Number: 85

Registered: 01-2005

Posted From: 172.133.172.14

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, June 23, 2005 - 12:52 pm: |

|

your pics also seam to reveal the amphicat axel type you have, unless they are your design they look like the better type cat axels.

these if im not mistaken have a provision for thrust load that you just don't find from other manufactures, good luck,

im inpressed so far! |

philip w.cox

Member

Username: Philipatmaxfour

Post Number: 23

Registered: 01-2005

Posted From: 209.226.175.59

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, June 25, 2005 - 10:46 pm: |

|

david

I understand that you or your friend MUDBUSTER

HAD A BREAKDOWN THAT EVENTUALLY REQUIRED THE REPLACEMENT OF THE 'JACKSHAFTS'. MY OWNERS MANUAL CALLS FOR THE FREQUENT CHECKING OF THE JACKSHAFT BUSHINGS. I THINK MAYBE THAT IS FOR THE MAX 2 BECAUSE I CAN'T SEE THE JACKSHAFT BUSHINGS ON MY MAX4. I HAVE GREASED THE INNER AND OUTER BEARINGS ON THE REAR AXLE, BUT I CANNOT FIND A GREASE NIPPLE ON THE 'JACKSHAFT'.

I THINK THE CHAIN IS DRIVEN BY A SPROCKET OFF OF THE T20 DIRECTLY ONTO THE REAR AXLE WITH AN ADJUSTABLE SPROCKET TO TAKE UP THE SLACK. AM I ALL MESSED UP? I DON'T WANT TO HAVE ANY BREAKDOWNS AT OLEAN N.Y. in three weeks!

Philip W. |

david berger

Intermediate Member

Username: Davidrrrd

Post Number: 86

Registered: 01-2005

Posted From: 172.131.130.135

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, June 26, 2005 - 09:28 am: |

|

philip you should be ok, my maxII is anchent and beat to death, the jack plates bolt tight on the sides and are loosend to adjust up or down -fwd or back to keep the chains from trany as well as chains for center axels properly tentioned,

mine's an 86 model year and was a techumpsa when it left the factory, since it has chainged into a 2 stroke kz440(arctic cat 440cc)38hp)

38 hp is a little much for the factory parts in drive train,i should have replaced the jack plates long before i had the trouble, as well as replaced the sproket set's for most axels ect..ect..

as mine were without half the teeth anyway, and my chains wer sreched out terably.

recreatives brought out the spair parrts i needed the next morning!

in tim s, case (mudbuster)

he had long wished to do an upgrade of his own on his maxIV ,

he had upgraded his 4 stroke briggs engine to produce well in the exess of 35 hp and also beat it to death,

but his only needed a master link on the day in question,

but it played into his plans to upgrade the whole drive train, he had a full set of custom axel sproketes made up for his splined modele max IV,

he had to remove each axels to replace the bearing in bearing cages or (bearing extentiones)

as well as outer fraim bearimng and inner bearing, but most inportently the old sproket set's.

they have set screws threw them that can be dificult to remove somtimes, and the factory ones were each sproket on seperet hubs,

tim has in places where there are more than 2 sproketes he has them on a special new double hub ,

also he replaced the set screws with hex head bolts, next to the snap ring upgrades the factory has recently anounced the chaing tim made to hex head bolts to anker his sprokets was a very wise choice.

and his own style dule sproket hubs are drilled in prime location for maintanence down the road, one bolt each axel, and thats all he needs!

but now i have writen all this my memory dose provide me with a little more on this,

yes he did have a little trtouble with ideler sprokets recently, and at olean, all i can sugest is to get some proper ideler sproket bolts and keep them in your on board tool box, then all you need is to chainge them out on the trail side while eating yer lunch and then youl be on your way. everyone should have some spairs master links and ideler sproket bolts as well as body plugs ect..ect..in an onboard tool box, chances are if you don't have them theres someone else at the event who dose,

(im too tired today to do a spell check) |

philip w.cox

Member

Username: Philipatmaxfour

Post Number: 24

Registered: 01-2005

Posted From: 209.226.175.59

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, June 27, 2005 - 12:54 pm: |

|

Thanks David

I will bring spares of almost everything. Can hardly wait till JULY 15. My nephew and his wife are coming with us and he will be doing the driving. Hopefully that will make my machine a little quicker on the downhill runs. Philip W. |

Larry Wright

Junior Member

Username: Xljimmy

Post Number: 12

Registered: 03-2005

Posted From: 68.248.139.204

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, July 06, 2005 - 05:59 pm: |

|

I completely redone the brakes and drove it again for about 10min. I am still using the 4 1/2" band brake usually seen in gocarts. It seems hard to just turn alittle. The brakes are either on or not doing much for the turning. So to turn alittle you have to just plip the lever quickly. I have never driven a 6x6 before so was wondering if that was normal? I also ripped a belt in half in the first 10min of riding it. Its size is A38. I noticed the pulleys arent perfectly aligned so I hope that was why. The only conserns right now are the life span of the brakes and if I have to go to a bigger sized drive belt. I'll keep you informed.

The axles and frame are original. I am not sure about other 6x6's but they slide in from the inside intile the hit the outer bearing. Then you tighten the jam nuts in the center of the frame untile there is no in or out play. They are only a 3/4" axle. |

Larry Wright

Junior Member

Username: Xljimmy

Post Number: 13

Registered: 03-2005

Posted From: 68.248.139.204

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, July 10, 2005 - 06:33 pm: |

|

Back to drawing board. From first test drive on there was a hard clicking sound and the drive chains would jolt when turning. First test drive I had know chain tensioners so I figured it was the chains slipping. Second test drive I put tensioners on but thought I should move them to differant location were they would work better. Today I relocated them and it still did it but seem to do it more. Then it started doing it straight and it dawned on me. The garden tracter diff is to weak and finally wouldnt go know more. So know I need to come up with a stronger setup. Maybe the diff out of a truck but I am going to have to come up with a reverse gear. |

Larry Wright

Junior Member

Username: Xljimmy

Post Number: 14

Registered: 03-2005

Posted From: 68.248.139.204

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, July 11, 2005 - 05:48 pm: |

|

Took transaxle apart and was right.

The spider gears are missing teeth.  |

david berger

Advanced Member

Username: Davidrrrd

Post Number: 101

Registered: 01-2005

Posted From: 172.170.246.233

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, July 12, 2005 - 02:50 pm: |

|

OUCH MAYBE THE NEW 4X4 SKID STEAR TRANS WILL FIT YOUR PLANS

http://www.av4atv.com/default.asp |

liflod

Member

Username: Liflod

Post Number: 25

Registered: 01-2005

Posted From: 65.209.67.204

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, July 12, 2005 - 03:39 pm: |

|

I've looked into those transmissions. I think its cheaper to buy a brand new T-20. |

david berger

Advanced Member

Username: Davidrrrd

Post Number: 102

Registered: 01-2005

Posted From: 172.170.246.233

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, July 12, 2005 - 04:15 pm: |

|

USED T-20'S THEN, THEY CAN BE HAD,

THE SHORT LIST WOULD BE TO START BY CALLING MR CLARK,

(THERE BULET PROOF YOU KNOW) |