| Author |

Message |

Dean

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

got a 1980 tb 8x8 myself I just bought,and plan on restoring.Can't seem to find a whole lot of info on them.Blacksheeps of the argo family,or what? |

jerry smith (Deerhunter)

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

Has anyone had a problem with the argo transmission, I have lost the high gear in my bigfoot. shift lever goes into high but I;am only getting low gear. please help....jerry |

Ray Carriere

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

I have an early 80's agro 8*8 and have redone the trany.I found all my bearing and bushings at my local bearing dealer and not at the argo dealer.

The prices i was quoted were way to high.

The trany is pretty straight forward.Not complicated by any means.

As for the person looking for info on his agro,i found all of my engine information in a lawn tractor manual in my local library.

I also had the 16 hp tec. and found lots of info.

I also found clutch info under snowmobiles.

I did alot of photo copying and made my own manual.

Good luck,the information is out there. |

Attex Bob

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

Jerry: No one else responded to your problem so I will give it a shot. First off, how does the lever feel when it goes in high? Does it feel loose? Does it feel normal, like gears are sliding on a shaft? I had my Argo tranny apart years ago and I don't remember much about it except it was very simple and built like it would see 500 horsepower!!!!!! I think there was a pin in the shifting coller, and I think this will be your problem. I assume you have checked the lever where it goes into the tranny to make sure that pin is ok and in place. They are very simple and very tough, so my guess will be something easy to fix. Good luck, and let us know what you find out. |

Tim O'K

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

I blew out the bearing on my bigfoot tranny yesterday. It was the top back bearing on the right side of tranny. It's the bearing for the reverse gear. Can I pop a new bearing in where the old one was, without spilting the case and taken out the tranny from the machine? It still has the snap clips in the tranny, but the bearing popped out or disinigrated! |

Tim O'K

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

I am going to attempt to fix it wednesday, hopefully I will be able to fix it without taken out the tranny. |

ACR

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

Have An older ARGO with single speed trans reverse blew out have replacement gear on the way anybody has a exploded view of the JTSS trans. and or helpful dissasembly/assembly tips to pass along would be helpful thanks |

Tom Pike

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

I have a 96 Argo Response. I bought it used and it was beaten up pretty bad, broken frame, dented front pipe, tear in the belly... I was always happy that the tranmission took me where I wanted to go but didn't like the fact it popped out of reverse constantly. I just accepted it as the only other argo I have been in did the same thing. I did notice the firewall didn't give the shifter any more movement left. Recently I decided to replace the bent nails the previous owner put in to hold the shifter in place (it has been a gradual restoration). I decided to put the transmission in reverse without the lever connected and see if it popped out while driving backwards under load. Low and behold it didn't! I couldn't see a way to moving the firewall. I didn't want to cut the firewall. So I bent the shifter slightly to give a bit more range to the left. Luckly the high gear had some extra clearence and now everything is working as it should. Thought I would post this in case somebody had another solution or the same problem. |

ACR

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

I think this argo had a similar problem with the roll pin on the gear selector as the reverse was not fully engaged ,teeth on the reverse idler gear were slowly destroyed . Also the belt doesnot appear to be correct. I just purchased the machine and am not familiar with argo but with engine running the belt is always turning,and the only way to shift into gear is to shut down the eng. and restart in gear as a result the gears in trans. have seen better times from previous owner trying to force into gear. Anyway I have the parts and will assemble soon. |

norm howard

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

responce to ACR. Pick up argo service manual, part # 673-00. It has all the exploded views & part numbers that you will need. It covers models from 1977 to 1986. |

David Keeso (Argomag)

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

I got a question for you ARGO experts- when my ARGO went down to the plant a month and a half ago, they replaced most drive chains, changed tranny fluid, new brake pads, new drive belt, bearings, flanges, seals etc. After putting about 15 hours on the ARGO since it was serviced, things were broken in like they are supposed to be- chains run smoothly, belt transferrs power smoothly etc. My problem now is that when i shift gears, it is very hard to move the gear shifter and when it gets into gear, it jumps and starts running itself slowly, but enough that you have to hold the brakes when you shift. What would cause this to happen, is the belt too tight, or is the engine idling too high? Someone told me that if i check the throttle cable routing, it may be getting pulled opened a little by something in the way, if not, adjust the screw where the cable goes onto the little piece on the engine that makes everything work (sorry, don't know the names of the parts or what they do) ? Is this really what i need to do or could it be something else.

I am leaving for the cottage this afternoon around 4 if i can get away that early so any help is greatly appreciated . |

ACR

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

Sounds like you answered your question. If engine & trans are lined up & nothing broke or bent maybe the engine is running too fast. |

fred sain

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, February 23, 2005 - 10:41 pm: |

|

David, If your problem is not the idle, sray belt dressing on your belt, you might also lubricate the front & rear clutch. |

Dave Keeso

Member

Username: Argomag

Post Number: 41

Registered: 01-2005

Posted From: 24.43.239.217

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, September 06, 2005 - 12:23 am: |

|

I ran the ARGO again this weekend, and still having the same problems with the shifting. The argo doesn't go into or out of gear easily at all, when it does it starts running itself and if you brake, the engine stalls. Going up steep inclines, engine slows down and it stalls, when idling, you can hear the clutch squeezing the belt and not letting it go. I had to put on my old drive belt and the same problem, still not letting it go, sits down about 1/4 inch from top of the driven clutch plate. Have lubed the hell out of it already- very frustration to deal with |

Jerry R. Nuss

Intermediate Member

Username: Jerrynuss

Post Number: 73

Registered: 02-2005

Posted From: 70.106.211.96

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, September 06, 2005 - 03:31 pm: |

|

Maybe the clutches need to be disassembled and rebuilt. |

Dave Keeso

Member

Username: Argomag

Post Number: 42

Registered: 01-2005

Posted From: 24.43.239.217

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, September 07, 2005 - 12:47 am: |

|

Jerry, is that something any dealer could do or would it have to go down to the plant and get done there? |

Jerry R. Nuss

Intermediate Member

Username: Jerrynuss

Post Number: 74

Registered: 02-2005

Posted From: 71.244.165.23

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, September 07, 2005 - 02:23 pm: |

|

A dealer should be able to do it. |

Jerry R. Nuss

Intermediate Member

Username: Jerrynuss

Post Number: 75

Registered: 02-2005

Posted From: 71.244.165.23

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, September 07, 2005 - 02:46 pm: |

|

The driven clutch on the transmission should expand as you increase the rpm, so the belt will move down into the clutch. The drive clutch on the motor will squeeze together on the belt and the belt will climb up in the clutch. It sounds like you are having trouble with the drive clutch.

The clutches require a lube with silicone spray at 50 hours or less of use. They are supposed to be rebuilt every 250 hours. If they have not been lubed or allowed to sieze then of course they would need to be rebuilt.

You write: When the motor is running you have to hold the brake or the machine will try and pull. If you put the machine up on jacks so the tires are not touching the ground then rev up the engine do the clutches move and the belt changes position. Have you sprayed the drive clutch? How much clearance is there between the sides of the drive clutch and the belt when the machine is not running, then at idle? Remove the belt and set your idle to 900rpm. Are ther any grooves worn in the drive clutch face where it touches the belt? |

fred sain arkansas argo dealer (Unregistered Guest)

Unregistered guest

Posted From: 12.213.88.36

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 08, 2005 - 10:07 am: |

|

Dave, Jerry has given you good advise. If the idle is at 900 RPM,s , then you have a clutch problem. A 99% chance that it is the drive clutch (the one on the engine). Put the machine in neutral and rev the engine up, the clutch should open quickly, and close quickly. When closed, you should have about a 1/2 inch gap between the pullies that move to engage the belt. P.S. Jerry do you need a job? You know your Argo,s well. |

Dave Keeso

Member

Username: Argomag

Post Number: 44

Registered: 01-2005

Posted From: 70.26.33.187

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, September 11, 2005 - 01:12 am: |

|

Fred, you mean their should be a 1/2 inch gap when you pull the belt together or actually on the clutch? |

Rogersmith

Member

Username: Rogersmith

Post Number: 47

Registered: 01-2005

Posted From: 4.244.87.57

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, September 11, 2005 - 10:16 am: |

|

Fred, talking about the belt being a 1/2" from the edge of the pulley halves.. reminds me that I put a shim in the drive clutch which allows the belt to ride out near the edge of the shivs. I wanted more top end on a response with a GU trans. It added several mph without changing the CVT otherwise. I've slept since I did it, but as I remember I put about a .050" thick spacer under the housing that holds the spring. |

fred sain arkansas argo dealer (Unregistered Guest)

Unregistered guest

Posted From: 12.213.88.36

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, September 13, 2005 - 10:03 am: |

|

Dave, I measured the gap on the front clutch, it is 1/4 inch gap when closed. I am not talking about where the belt runs, I am talking about the gap just to the side of where the belt runs. That gap should expand quickly when you rev up the engine, and contract quickly when you let off the gas. |

Dave Keeso

Intermediate Member

Username: Argomag

Post Number: 52

Registered: 01-2005

Posted From: 24.43.239.217

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, October 10, 2005 - 05:07 pm: |

|

I know i've asked this several times now, but this is the last. Im my posts above I described the problem with the clutch on my ARGO- i had a good look at it running this past weekend and the drive clutch isn't going fully together for some reason, as a result, the belt isn't sitting on the driven clutch properly, it sits down in it a bit even with the engine shut off. I couldn't even get the belt off yesterday because it was so tight and im using an old belt that I already replaced- I took out the good belt last time i was there to avoid damaging it. If the drive clutch has to be rebuilt, can i take the ARGO to anyone who can work on the clutch or is the clutch set up specifically for the ARGO or just like any other clutch for a snowmobile? I do not want to take it somewhere like an engine repair shop and then get it back and it doesn't run properly. is it simply just a case of rebuilding it and putting it back on? or does it require factory specific adjustments? and what am i looking at $ wise? |

Jerry R. Nuss

Intermediate Member

Username: Jerrynuss

Post Number: 92

Registered: 02-2005

Posted From: 70.106.204.210

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, October 10, 2005 - 05:42 pm: |

|

It sounds like you might as well have both clutches rebuilt. I'd take them to a local Argo dealer. If no one is local send them to a dealer and get an estimate before the work is done. You can also price out a new set and compare that to rebuilding them. The driven clutch will have the belt down in it a little but it will move down in with an increase in rpm. The drive clutch does the opposite and will squeeze together. Have you sprayed both of them with silicone spray? They are both items that are supposed to be serviced so a dealer should be able to do it without any problem and have access to parts. There are some springs and plastic slides that may need replaced. |

Jerry R. Nuss

Intermediate Member

Username: Jerrynuss

Post Number: 93

Registered: 02-2005

Posted From: 70.106.204.210

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, October 10, 2005 - 06:19 pm: |

|

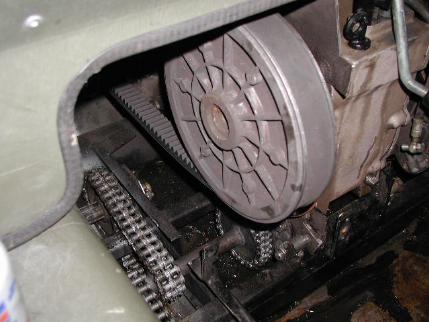

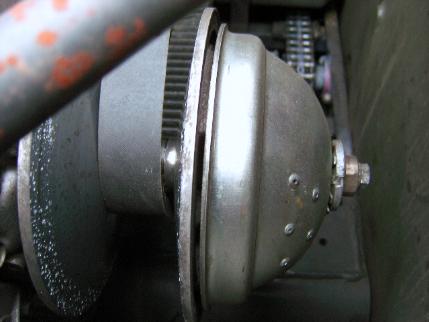

Here is a photo of the drive clutch and driven clutch. The photo of the driven clutch has a worn belt. The photo of the drive clutch is with a new belt. The position on the driven clutch will vary depending upon the wear of the belt.   |

Sean McConnell

Junior Member

Username: Bookm

Post Number: 11

Registered: 09-2005

Posted From: 69.159.216.86

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, October 11, 2005 - 02:29 pm: |

|

If the belt is tight with the engine off, AND the Secondary Clutch (on gearbox) is not fully closed, it suggests to me that the Primary Clutch (on engine) is not fully open. Does the belt have slight side-to-side play on the Pimary? It should not be squeezed by the spool at all. If it's tight, the clutch is sticking on it's shaft. I would pull it apart and inspect.

Any snowmobile or small engine shop can service these clutches. They're not made by ARGO, just purchased and bolted on ;) |

Dave Keeso

Intermediate Member

Username: Argomag

Post Number: 53

Registered: 01-2005

Posted From: 142.55.209.212

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, October 12, 2005 - 12:12 pm: |

|

THANK YOU, THANK YOU, Now i am certain its the clutches that are acting up. Much appreciate the help and the pics from all. And Sean, thank you for your imput also, That also saves me a trip with the trailer to get it fixed. The clutch is the last thing i need fixed to get my machine running 100% again and good for another 200 hours or so. Thanks again to all! |

Skip Saul

New member

Username: Giantdog

Post Number: 9

Registered: 10-2006

Posted From: 67.142.130.56

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, June 01, 2007 - 07:55 pm: |

|

I Need some Help and any you can give would be appricated the Trans in my argo went south the reverse gear went out it will back up if i hold the lever over tight it will back up with jerkey movement and a lot of noise I have a new trany coming but would like to fix this one if at all possible how hard are they to change and what does it intail |

Jerry R. Nuss

Senior Member

Username: Jerrynuss

Post Number: 531

Registered: 02-2005

Posted From: 131.230.43.5

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, June 01, 2007 - 11:27 pm: |

|

You can get the service videos from Becky Orr or Brandon. The video has a step by step tear down of the transmission. It is not very difficult with basic tools. |

Skip Saul

Junior Member

Username: Giantdog

Post Number: 10

Registered: 10-2006

Posted From: 67.142.130.23

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, June 02, 2007 - 12:20 pm: |

|

Thanks A bunch I will contact them at this point i am all most lost as what to do how hard is it to change trans how long dose it take and how about brakeing the chain what do i do there |

Jerry R. Nuss

Senior Member

Username: Jerrynuss

Post Number: 532

Registered: 02-2005

Posted From: 131.230.43.23

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, June 02, 2007 - 05:59 pm: |

|

You should be able to loosen the transmission mount bolts and then turn down the bolt that lifts the rear of the transmission to adjust the drive chains. The chains should have a master link that you can remove. I'd expect 30 minutes to an hour to remove the transmission depending on if you have tools handy and nothing is rusted or stuck. |

Skip Saul

Junior Member

Username: Giantdog

Post Number: 11

Registered: 10-2006

Posted From: 67.142.130.45

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, June 02, 2007 - 10:57 pm: |

|

Tahnks so much you have no idea how much you have helped this old war horse the gears are starting to turn now thay are a little rustey but thay are starting to turn thanks so much |

Skip Saul

Junior Member

Username: Giantdog

Post Number: 16

Registered: 10-2006

Posted From: 67.142.130.19

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, June 15, 2007 - 02:35 am: |

|

Transmission up date the trans is in it went in a hole lot easer then it came out i went for a ride to day it shifts hard i assume becouse its new it seems to me that low gear is a bit higher then the old one but high gear seems to be the same right ?????? but other then that it runs great it was so fun to drive i put to hours it PS I could not find any stp to dump in but i did find some power punch extream for heavy equiptment made to reduce wine in strate gears and to satchrate gear bearring and readuce heat so i put that in along with some gear grease the trans dose not make near as much noise as the old one did way befor it went out |

Eddie L. Beddingfield

Intermediate Member

Username: Argo2003

Post Number: 63

Registered: 08-2006

Posted From: 64.12.116.204

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, June 15, 2007 - 07:54 am: |

|

Skip as long as they sent you the same letter designation on top of the trans,it should have the same gearing.I cant remember off the top of my head what the Conquest used,but want to say the H ,I would have to check my books to make sure.However if it is the same letter it is the same gearing. |

Skip Saul

Junior Member

Username: Giantdog

Post Number: 17

Registered: 10-2006

Posted From: 67.142.130.54

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, June 15, 2007 - 11:45 pm: |

|

The trans that i took out it has MU and the new has GU desingation on it so that is probbley it well it is some thing i am going to have to live with. it is going to make it a little diffucalt to plow snow this winter but it will have to do |

Rogersmith

Advanced Member

Username: Rogersmith

Post Number: 302

Registered: 01-2005

Posted From: 70.234.138.203

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, June 16, 2007 - 12:37 pm: |

|

The G is a lower geared trans. There's a two gear set that interchangable, that's the difference between any of the pre avenger trans. It affects all gears, low, high, reverse. For an 8 wheeler a GU makes it easier to turn and haul loads, or fit the new 24" tire. |

Skip Saul

Junior Member

Username: Giantdog

Post Number: 18

Registered: 10-2006

Posted From: 67.142.130.47

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, June 17, 2007 - 01:10 am: |

|

Thanks for the info it shure seems to run better all around I dnt now about faster but better it dose shift easer |